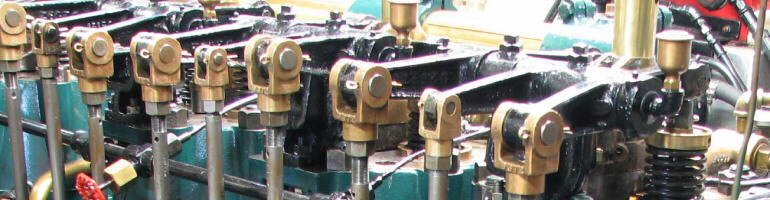

Valve-grinding: a team effort

This week, I finished cleaning all the valves for the Thea Foss. Engineer Ron ground the valves and observed that “the first one is fun and the rest of the 24 are boring,” which I definitely agree with. Then Vince came out of retirement and over the mountains to grind the seats, and we had a nice team to get the job done efficiently.

A visit to the Cape Cross

Later this week, I visited the crew of the Enterprise-powered fish tender Cape Cross. The engine’s running well and best of all, the boat is gainfully employed.

Dry-suit repairs

After last week‘s brush with carotid sinus reflux, diver Duane helped me replace the neck seal in my dry suit. Apparently adding a latex neck seal to a neoprene suit is pretty common, and it’s an easy process. First, I coated the sealing area with AquaSeal and let it cure, then I put another coat on to adhere the latex. Then I trimmed it and put one more bead of AquaSeal on edges, and the suit was ready to go.

Giving the CWB a lift

On Saturday, I worked with Sterling Marine Services Llc to level out some of the floating docks at the Center for Wooden Boats by installing some new barrels. Once we got we got a system down, it went really fast. Sterling Marine Services Llc has posted more about it in their brand-new blog here.

Repairs and updates on the Island Champion

I visited the Island Champion this week to isolate the overboard through-hull fixture from the engine. This is an area of excessive stray voltage, which induces electrolysis in the surrounding planks and makes them rot out a lot faster – according to our resources, it’s like nail sickness from increased alkalinity.

I installed piece of hose to separate the engine from the through-hull fitting, which disrupts (in theory) the electrical current running between them:

This should hopefully stop the electrolysis and save the hull timber a little longer.

Also, boat buyers take note: the Island Champion is not for sale anymore.

To bond or not to bond

This brings up the age old-argument: “to bond or not to bond.”

To bond, or not to bond: that is the question:

Whether less noble metals should suffer

The slings and arrows of outrageous corrosion,

Or to take arms against a sea of troubles,

And insulate them. To dielectric: to isolate;

No more; and by isolate to say we end

The corrosion and the thousand natural shocks

That hulls are heir to, ’tis a consummation

Devoutly to be wish’d. To dielectric, to isolate;

On the subject of galvanic corrosion: the way I read it, impressed current is best but anodes are easier and more common. If using anodes, quantity and placement are very important to get right and bonding or isolating is addressed on a case-by-case basis.

Some fittings below the waterline, if isolated, can take a long time to degrade, while others will need to be wired to the anode using a resistance-free electrical circuit with heavy-gauge wire, good connections, and keeping it out of the bilge water. When working with mili-volts, a loose connection is no connection: the mili-volt will not jump a gap. I think it is this sloppy wiring that causes bias in our maritime tradesmen.

More important than the bonding and anoding, boats and equipment should be inspected and repaired regularly – and repairs should be made before small problems are catastrophic. It pains me to hear folks argue about bonding while the boat is sinking. While limiting galvanic activity is important – keep it in perspective!

Update on the Maris Pearl

Meanwhile on the Maris Pearl, we’re down to just looking for the shaft that attaches to the piston in the reversing mechanism and the camshaft gear.

Who’s got one? Any drawings? Anything? Help?

Work begins on the Arthur Foss

The Northwest Seaport started their “Stop the Leaks” project on the Arthur Foss; it sounds like the first step was to take off the big rubber fender on the bow. They took a lot of pictures of it – and better yet, wrote a blog about it! Check it out here!